Recycled Rubber: A Win For Communities, the Environment, and the Economy

Creating A Cleaner Environment

Eighty percent of tires are recycled and reused annually, preventing millions of scrap tires from being dumped in landfills, lakes, abandoned lots, and along the side of the road. Instead, these tires take on another life as playground equipment, nursing home floors—even the soles of shoes. In fact, over 12,000 synthetic turf sports fields use crumb rubber infill from recycled tires, keeping 110 million tires out of landfills.

Recycling also saves impressive amounts of energy, ultimately reducing greenhouse gas emissions and slowing global warming. For example, recycling four tires reduces CO2 by about 323 pounds, which is equivalent to 18 gallons of gasoline.

Click images to enlarge:

Building Safe Communities

From school playgrounds to community tennis courts, recycled rubber provides a shock-absorbent material that helps cushion falls and spills. Compared to grass fields, the shock absorbency provided by multiple layers of crumb rubber infill in synthetic turf fields protects athletes from accruing significant surface impact injuries, including concussions.

Moreover, recycled rubber surfaces can be designed to be widely usable, accessible, and ADA-compliant—a feature that grass and other industrial surfaces lack. Recycled rubber's durability and resiliency makes it a great choice for use in commercial settings and hospitals. It's water resistance, so it can't be damaged by spills or moisture and its high degree of surface friction make it slip resistant, which is especially useful for healthcare and nursing facilities.

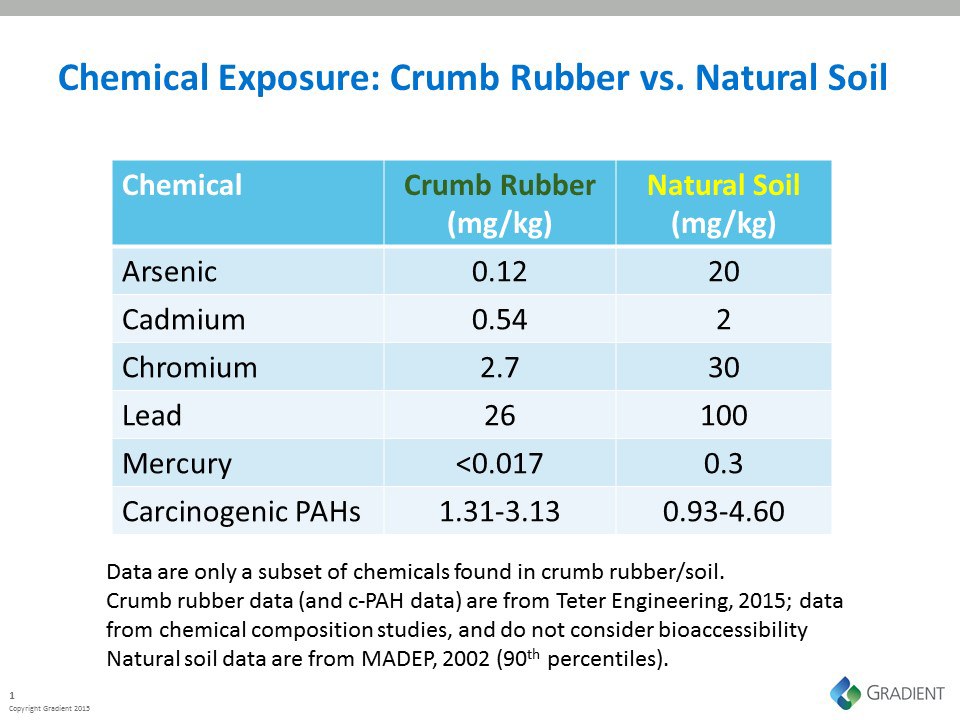

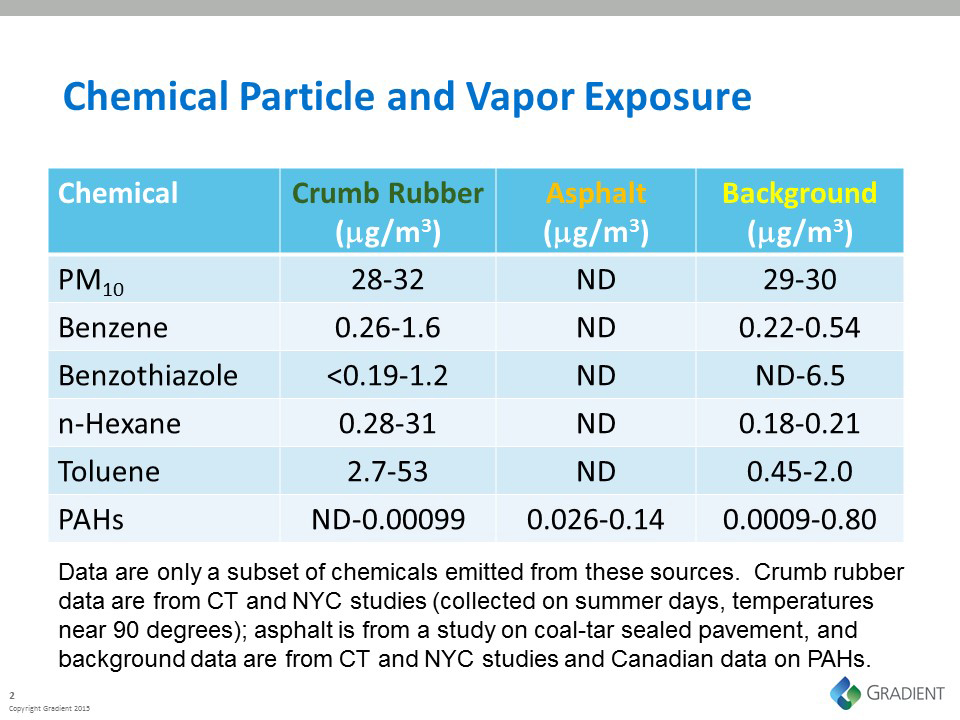

Recycled rubber is a scientifically-proven safe material. More than 90 technical studies on the various applications for recycled rubber have concluded there are no significant health risks.

Supporting Local Economics

Thanks to its durability, crumb rubber is a better value product for people and communities across America. The cost of installing and maintaining a synthetic turf field is three times less expensive than the cost of a grass field over the same period of time.

The rubber recycling industry also boosts local economies and creates manufacturing jobs across the country. The industry generates more than $2.5 billion in economic activity annually and contributes more than $295 million in federal, state, and local tax revenue. Moreover, the recycled rubber industry employs more than 12,000 people nationwide, providing more $500 million in employee wages each year.

Click image to enlarge:

Benefits Of Artificial Turf

When considering replacing an old field with a new one, or embarking on a brand new project, the question of whether to use synthetic turf or grass comes up early and often.

Grass requires costly and intricate maintenance that makes upkeep difficult for many institutions and municipalities to keep their fields in a playable condition that is safe enough for its players. Synthetic turf requires more limited maintenance and it provides a very playable surface for years. There is no watering, no mowing, and no fertilizers or pesticides needed to maintain synthetic turf, conserving resources, including millions of gallons of water yearly, and budget.

Synthetic turf also enables longer play deeper into colder seasons, and extended hours of use given the lack of recovery time needed—leading to further revenue generation from renting the field.